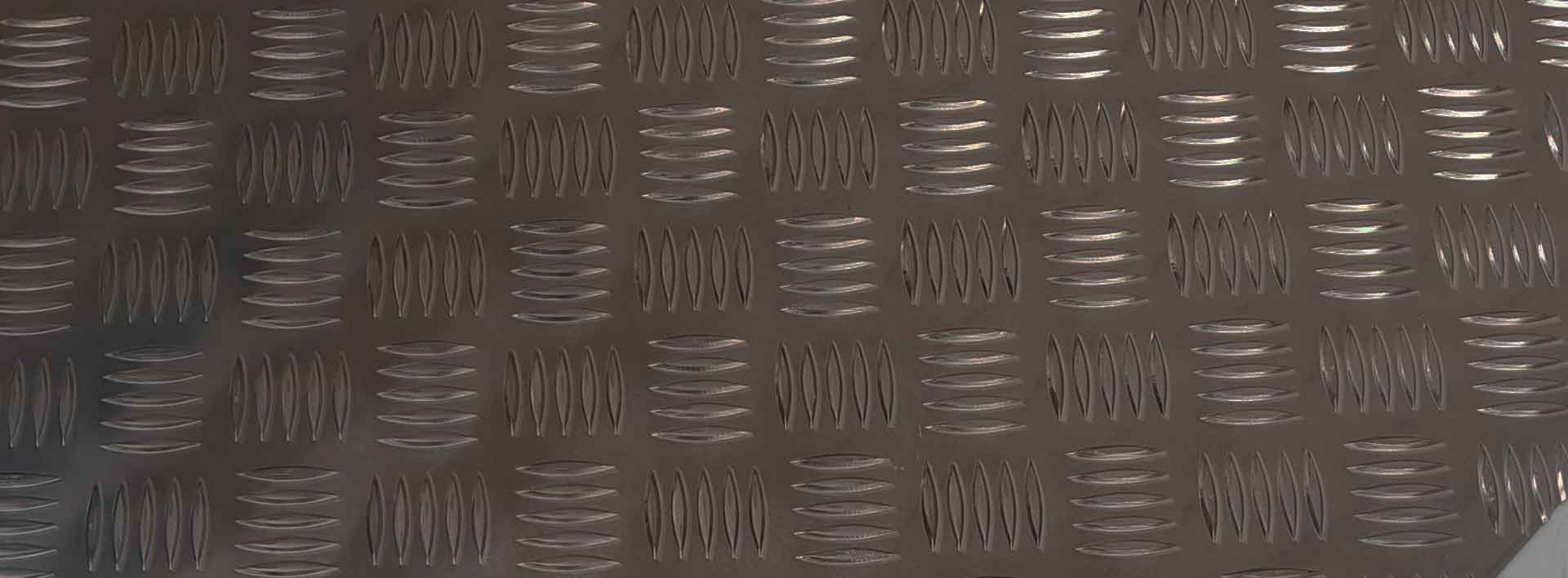

IN AW-5754 DAMERO

Available formats: Checkerboard with 5 Sticks

The Aluminum Alloy Magnesium EN AW 5754 Checkerboard or non-slip sheets with 5-tooth design belongs to an alloy of high mechanical resistance, with good resistance to corrosion, comparable to that of pure aluminum in general and better than that of aluminum, if Marine environment is all about.

It is applied in cauldron, either welded or riveted. Indicated for the manufacture of pressure vessels: for the production and storage of liquefied gases (O2, N2, A, He). Due to its high resistance to corrosion in marine environments, it is very suitable for shipbuilding, refrigerators, ship superstructures, lifeboats, floats.

Heat treatments:

Annealing: 30 min. at 2 hours at 345 ° C - 380 ° C.

Forging: Optimum temperature 450 ° C (range 350 ° C to 510 ° C)

Available sizes:

Checker plate 1000 x 2000 cm

Checkerboard of 1250 x 2500 cm

Checkerboard plate 1500 x 3000 cm

Chemical Composition According to EN 573? 3

|

%

|

Si

|

Fe

|

Cu

|

Mn

|

Mg

|

Cr

|

Zn

|

Ti

|

Bi

|

Mn + Cr

|

Others

|

Al

|

|

Min. |

- |

- |

- |

- |

2,6 |

- |

- |

- |

- |

0,1 |

- |

- |

|

Max. |

0,4 |

0,4 |

0,1 |

0,5 |

3,6 |

0,3 |

0,2 |

0,15 |

- |

0,6 |

0,15 |

Rest |

Chemical Composition According to EN 573? 3

|

Element

|

Min.%

|

Max. %

|

|

Si Fe Cu Mn Mg Cr Zn Ti Bi Mn + Cr Others Al |

- - - - 2,6 - - - - 0,1 - - |

0,4 0,4 0,1 0,5 3,6 0,3 0,2 0,15 - 0,6 0,15 Rest |

International Equivalences

|

USA

|

SPAIN

|

FRANCE

|

GERMANY

|

GB

|

SWEDEN

|

SWITZERLAND

|

CANADA

|

ITALY

|

|

AA |

UNE |

AFNOR |

DIN (1712-1725) |

BS |

SIS |

VSM |

ALCAN |

UNI |

|

5754 |

L-3390 |

A-G3M |

AlMg3 |

- |

4130 |

Peraluman-300 |

57S |

3059 |

International Equivalences

| USA | AA | 5754 |

|---|---|---|

| Spain | UNE | L-3390 |

| France | AFNOR | A-G3M |

| Germany | DIN (1712-1725) | AlMg3 |

| GB | BS | - |

| Sweden | SIS | 4130 |

| Switzerland | VSM | Peraluman-300 |

| Canada | ALCAN | 57S |

| Italy | UNI | 3059 |

General Physical Properties

|

Module

Elastic N / mm² |

Weight

specific gms / cm³ |

Temperature

of fusion in ° C |

Coefficient of

linear dilation ? m / mK |

Conductivity

thermal W / mK |

Resistivity

electric ?? m |

Conductivity

electric % IACS |

Potential of

dissolution V |

|

70.000 |

2,70 |

590 - 645 |

23,8 |

132 |

53 |

35,3 |

-0,85 |

Physical Properties

| Elastic module N / mm² |

70.000 |

|---|---|

| Specific weight gms / cm³ |

2,70 |

| Melting temperature in ° C |

590 - 645 |

| Linear expansion coefficient ? m / mK |

23,8 |

| Thermal conductivity W / mK |

132 |

| Electrical resistivity ?? m |

53 |

| Electric conductivity % IACS |

35,3 |

| Dissolution potential V |

-0,85 |

Technological skills (MB Very Good | B Good | C Correct | R Regular | M Bad)

WELDING

- To the flame (MB)

- Al argon under argon gas (MB)

- By electrical resistance (MB)

- Braised (R)

ANODIZED

- Protection (MB)

- Decorative (B)

- Hard Anodized (MB)

MECHANIZATION

- Chip Fragmentation (R)

- Surface brightness (MB)

REPUJADO

- In state: O (R)

NATURAL BEHAVIOR

- In rural environment (MB)

- In industrial environment (MB)

- In marine environment (MB)

- In seawater (B)

COVERING

- Lacquered (B)

- Galvanized (B)

- Chemical nickel (B)

EMBUTITION

- By expansion (B)

- Deep drawing (B)

FOOD

- Food use (MB)

Formats

- Aluminum Sheet Magnesium Alloy EN AW 5754 Checkerboard